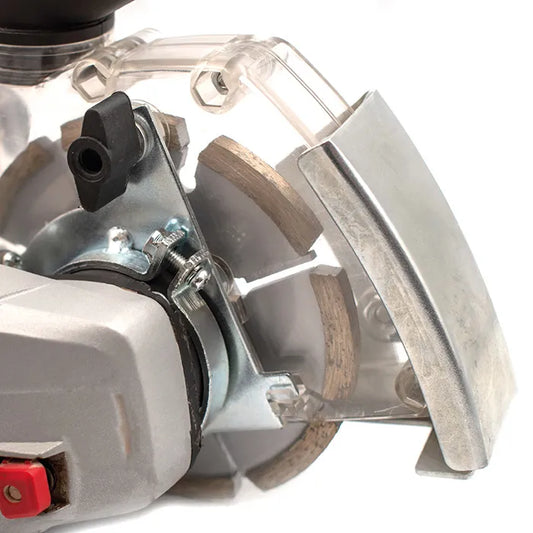

Concrete Grinder Discs

Discover our premium range of floor grinder accessories and grinding wheels designed for professional results.

Whether you need a durable concrete floor grinder wheel or high-performance concrete grinding discs, we offer top-quality grinding cup wheels to tackle any surface preparation job. Shop now for reliable, long-lasting tools that make concrete grinding faster and easier.

-

Marcrist HU350U Multi-Material Diamond Grinding Head

Universal Segmented Diamond Grinding Cup Wheel The Marcrist HU350U Universal Segmented Diamond Grinding Cup is a versatile tool designed for rapid removal and finishing work on various surfaces, making it ideal for both professional trades and DIY enthusiasts. Product Specifications Sizes Available: 115mm (4...- from £53.25

- from £53.25

- Unit price

- per

-

Marcrist HU850C Universal Diamond Grinding Head

Marcrist HU850C Universal Grinding Wheel Head is capable of grinding Concrete, Plaster, Render and Tile Adhesive. Experience unparalleled grinding performance with the Marcrist HU850C Universal Diamond Grinding Wheel. This high-performance tool is designed to handle a variety of materials with ease, including concrete, plaster,...- from £117.42

- from £117.42

- Unit price

- per

-

Marcrist HP850C Grinding Cup Wheel for Paint Removal

The Marcrist HP850C Diamond Grinding Head is your ultimate solution for paint removal, surface preparation, and concrete leveling. Designed with durability and efficiency in mind, this versatile grinding head excels in reducing, leveling, and preparing concrete surfaces. Whether you're tackling tough coatings like carpet...- from £117.42

- from £117.42

- Unit price

- per

-

Marcrist HU850 Multi Material Diamond Grinding Head

Marcrist HU850 Diamond Grinding Head For Universal Applications. The Marcrist HU850 Multi-Material Diamond Grinding Head is a versatile and high-performance tool designed to handle a wide range of materials and applications. Its T-segment design offers the benefits of both turbo and segmented heads, making...- from £58.11

- from £58.11

- Unit price

- per

-

Marcrist HU250 Diamond Grinding Cup for Universal Applications

Universal Applications Blade for Standard Grinding The Marcrist HU250 Grinding Blade is a versatile tool designed for a variety of standard grinding applications, offering durability and efficiency. Product Specifications Type: Grinding Cup for universal applications Compatibility: Designed for use with both angle grinders and...- £22.37

- £22.37

- Unit price

- per

-

Marcrist HPCD850C PCD Grinding Head - Floor Preparation Cup Discs

Polycrystalline Diamond PCD Grinding Head For Thick Coatings. The Marcrist HPCD850C PCD Grinding Head is an ultra-aggressive tool designed for rapid removal of tough, thick coatings such as epoxy, mastic, bitumen, and carpet residue. Featuring polycrystalline diamond (PCD) tips, this grinding head delivers unmatched speed...- from £224.16

- from £224.16

- Unit price

- per

-

Marcrist HF850C Diamond Turbo Grinding Head for Hard Building Materials

Marcrist HF850C Precision & Durability for Hard Building Materials The Marcrist HF850C Diamond Turbo Grinding Head is designed for professionals seeking ultimate precision in grinding, leveling, edge grinding, and cleaning. Its robust diamond-turbo design guarantees exceptional performance and an extended life span, making it the...- from £69.97

- from £69.97

- Unit price

- per

-

Marcrist HU350A Diamond Grinding Head

Universal Diamond Cup Grinding Wheel For Soft Concrete, Masonry and Render The Marcrist HU350A Diamond Grinding Head is a high-performance tool engineered for various standard grinding applications, specifically designed to handle tough materials like asphalt and soft concrete. This grinding head is ideal for...- from £65.11

- from £65.11

- Unit price

- per