Premium Diamond Cutting Discs & Grinder Blades

Discover high-performance diamond cutting discs, grinder blades diamond, and diamond cutting wheels designed for precision and durability.

Ideal for construction pros and DIYers seeking top-tier cutting power.

-

Marcrist MI650 Universal Angle Grinder Diamond Blade

MI650 Segmented Diamond Disc For Fast Precision Cutting Through a Wide Range of Materials High diamond density for quicker cutting. 15mm segment height enables cutting through all building materials. Features laser welding and an armoured core for durability. The Marcrist Mi650 diamond cutting blade...- from £22.85

- from £22.85

- Unit price

- per

-

Marcrist BF750 Precision Turbo Cutting Diamond Blade

Marcrist BF750 High-Quality, Turbo-Cutting Diamond Blade. The Marcrist BF750 Precision Turbo Diamond Blade is engineered for professionals seeking unmatched cutting speed, durability, and precision. Designed for versatility, it excels in both stationary machines and angle grinders, making it ideal for a wide range of...- from £23.60

- from £23.60

- Unit price

- per

-

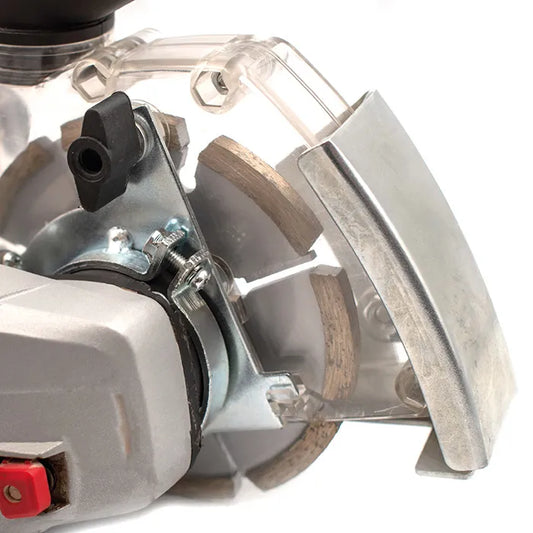

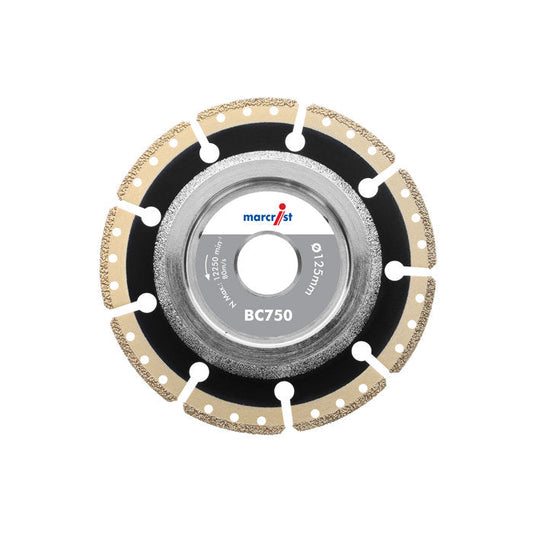

Pipe Cutting and Chamfering Diamond Disc Marcrist BC750

125mm Multi-Action Diamond Disc - The Ultimate Pipe Cutting Tool with Built-In Chamfering Meet the advanced pipe cutting tool engineered for precision, power, and perfection - designed to streamline every pipe cut with a flawless finish. Whether you're cutting a PVC pipe, tackling tough...- £81.83

- £81.83

- Unit price

- per

-

Universal Segmented Cutting Disc For Angle Grinder, SX-10 PRO for Masonry Cutting

Cutting Disc for angle grinder SX-10 PRO Segmented Diamond Cutting Blades for General Masonry Cutting The SX-10 PRO Segmented Diamond Cutting Blade is a versatile and high-performance tool designed for cutting through a variety of construction materials. It is ideal for both professional contractors...- from £8.95

£9.95- from £8.95

- Unit price

- per

-

Segmented Hand Grinder Cutting Discs SX-12 Max

My Tool Expert SX-12 Max Segmented Angle Grinder Blades for Masonry, Stone, Bricks, Concrete Cutting The SX-12 Max Segmented Diamond Cutter Disc for Angle Grinders is a high-performance cutting tool designed for professionals and DIY enthusiasts alike. These grinder blades are engineered to handle...- from £13.39

- from £13.39

- Unit price

- per

-

SX-16 MegaMax Premium Diamond Disc Saw Blade

SX-16 MegaMax Segmented Diamond Cutting Discs - Professional Diamond Blades for General Masonry Cutting The SX-16 MegaMax Segmented Diamond Cutting Blade is engineered for builders, contractors, and serious DIY users who demand precision cutting and long-lasting performance. Built with advanced diamond blade technology, This...- from £17.95

- from £17.95

- Unit price

- per

-

Marcrist MA750 Diamond Table Saw Blade for Marble, Slate, Limestone

Marcrist MA750 Professional Diamond Table Saw Blade The Marcrist MA750 Professional Diamond Table Saw Blades are engineered for ultimate performance and durability. MA750 premium blade is ideal for use with table saws, tile saws, and bridge saws, making it a versatile choice for professionals....- from £174.53

- from £174.53

- Unit price

- per

-

Marcrist WS750 Masonry Wall Chasing Diamond Blade

Premium Professional Quality Masonry Diamond Wall Chase Blade Marcrist WS750 The Marcrist WS750 Wall Chasing Diamond Blade is designed for professionals who demand both exceptional durability and performance. Engineered with a 10mm diamond segment and double laser welding, this blade ensures optimal stability and precision....- from £49.10

- from £49.10

- Unit price

- per

-

Marcrist Mi350 Universal Diamond Blade

Marcrist Mi350 Professional Trade Quality Angle Grinder Diamond Blade. These diamond blades are designed to reliably cut through a variety of building materials including concrete, concrete products, and concrete roof tiles. Whether you're working on block pavers, blockwork, or natural stone, the Marcrist Mi350...- from £11.74

£5.98- from £11.74

- Unit price

- per

-

Marcrist Mi850 45 Year Anniversary Twin Pack

Celebrate 45 Years of Innovation with Our Exclusive Diamond Blade Twin Pack Elevate your cutting experience with this special 45th-anniversary twin pack of diamond blades, crafted for professionals who demand durability, precision, and the best cost-efficiency on every job. These blades combine advanced engineering...- £197.27

- £197.27

- Unit price

- per

-

Marcrist BF850 45 Year Anniversary Twin Pack

Celebrate 45 Years of Innovation with the Exclusive BF850 Diamond Blade Twin Pack Marking 45 years of pioneering in diamond blades, this limited-edition twin pack of BF850 diamond blades is engineered for professionals who demand top-tier performance and exceptional value with each cut. This...- £142.96

- £142.96

- Unit price

- per

-

Marcrist BF850 & Mi850 45 Year Anniversary Twin Pack

Celebrate 45 years of cutting-edge innovation with this exclusive twin pack of diamond blades. Designed for professionals seeking superior performance and the lowest cost-per-cut. This special anniversary edition brings together the best of our technology in the BF850 and MI850 blades, offering unmatched durability, precision,...- £167.00

- £167.00

- Unit price

- per

-

Marcrist CC750 Premium Diamond Blade for Smooth Porcelain Tile Cutting

Marcrist CC750 Pro Radius Cutter – Perfect Curves on Porcelain Tiles. The Marcrist CC750 Diamond Radius Cutter is a must-have for professionals looking to achieve flawless curves and precise shapes in tiling and landscaping projects. Crafted with premium diamond technology, this cutter is designed...- £53.37

- £53.37

- Unit price

- per

-

Marcrist HW850D Insulation Materials Cutting Disc

Smooth, Effortless Cuts in Insulation Materials Designed for use with angle grinders and circular saws, this cutting disc effortlessly slices through insulation materials like butter, offering unmatched precision and speed. Features & Benefits: Ultra-Thin Design: Provides exceptional speed and precision in every cut, minimizing...- £77.91

- £77.91

- Unit price

- per

-

Marcrist Mi250 Segmented Diamond Blade For Masonry

MI250 Diamond Cutting Blade is the performance-leading choice for general-purpose cutting in the building trade. Engineered with a High-Tech general-purpose diamond bond, this blade excels in cutting a variety of materials you may encounter on a building site. Designed for fast, clean cuts on...- from £7.56

- from £7.56

- Unit price

- per

-

Marcrist Mi750 Universal Diamond Cutting Disc

Marcrist Mi750 Universal Diamond Cutting Disc – The Ultimate Long Life Diamond Blade for Heavy-Duty Concrete Cutting Power through even the toughest jobs with the Marcrist Mi750 Universal Diamond Cutting Disc – your professional-grade solution for diamond cutting across all types of concrete and...- from £56.87

- from £56.87

- Unit price

- per

-

Universal Segmented Grinding Disc, SX-10 Superior

SX-10 Superior Segmented Diamond Cutting Blades for General Masonry Cutting The Ultimate Cutting Solution for Builders & DIY Experts The SX-10 Superior Segmented Diamond Cutting Blade is a high-performance cutting disc designed for tough, everyday jobs. Built for speed, durability, and precision, this premium diamond...- from £7.45

- from £7.45

- Unit price

- per

-

3 in 1 Diamond Cutting Disc Marcrist CGF750, Grinding and Finishing

Marcrist CGF750 Precision Diamond Cutting, Grinding, Edge Grinding, Bevelling, and Finishing, all with one Blade...! The Marcrist CGF750 Precision Diamond Cutting Disc is an essential tool for professionals and DIY enthusiasts seeking versatility and efficiency. Designed to handle cutting, grinding, edge grinding, bevelling, and...- from £49.14

- from £49.14

- Unit price

- per

-

Marcrist BF850T Diamond Turbo Table Saw Blade

Ultimate performance diamond turbo rim, runs almost silent! Elevate your cutting experience with the Marcrist BF850T Diamond Turbo Table Saw Blade, engineered for professionals who demand precision, durability, and minimal noise. Featuring the innovative SilentMAX technology, this blade ensures near-silent operation without compromising on...- £191.32

- £191.32

- Unit price

- per

-

Professional Floor Saw Blade for Concrete Marcrist CB750

Marcrisr CB750 Professional diamond concrete saw blade for floor saws 5.0 - 15 HP. This professional diamond concrete saw blade is designed for floor saws ranging from 5.0 to 15 HP. It excels in cutting hard concrete, heavily reinforced concrete, and flint concrete, making...- from £255.96

- from £255.96

- Unit price

- per