Diamond Polishing

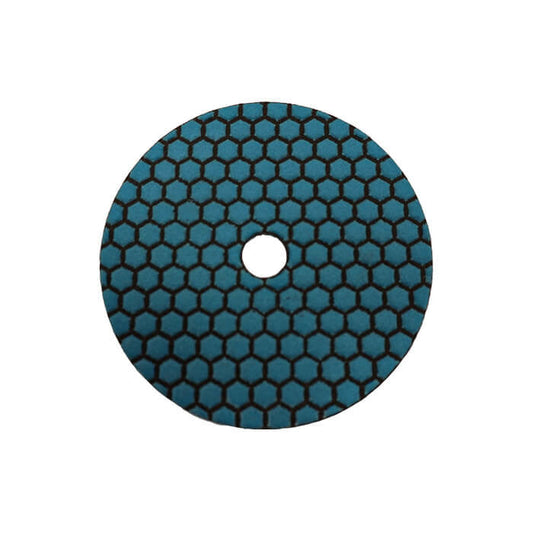

Diamond Grinding Pads

Diamond abrasive pads feature a diamond-studded honeycomb structure, ideal for grinding and polishing various surfaces. Available in different variants for specific purposes, these pads offer versatile applications. Below is an overview of the types and uses of diamond grinding pads.

Grit Sizes and Applications

Our diamond sanding pads are available in the following grits and diameters: 50, 100, 200, 400, 800, 1500, and 3000 in 100 mm, Ø 115 mm, and Ø 125 mm.

Suitable materials include granite, natural stone, glass, marble, and tiles.

Buying Diamond Grinding Pads: Sets or Individual?

For projects involving multiple grinding or polishing steps, such as working with glass or marble, a complete grinding pad set is recommended. This ensures you have a variety of pads and polishing discs with different grits.

-

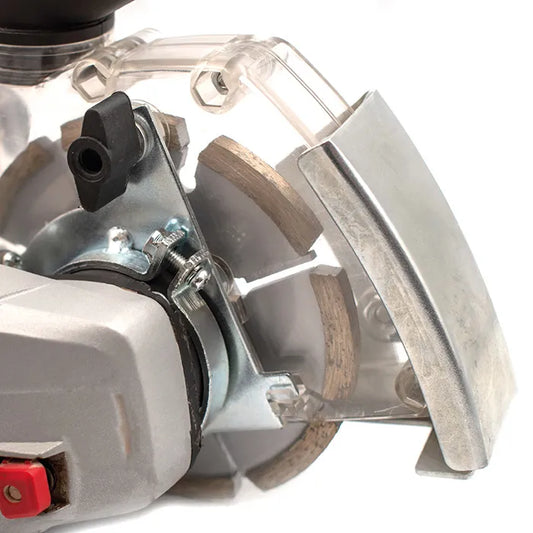

Marcrist Diamond Polishing Disc DP850

The Marcrist Diamond Polishing Disc DP850 is a top-grade component designed for optimal polishing performance. The Marcrist Diamond Polishing Disc DP850 is a high-performance, durable polishing solution that significantly outlasts conventional sanding discs by up to 100 times. Designed for use on standard angle...- from £33.40

- from £33.40

- Unit price

- per

-

Diamond Hand Polishing Pads

Diamond Tile Edge Polishing Pads Coarse #50 Fine Grit #100 Ultrafine Grit #200 Diamond Hand Polishing Pad for Correcting/Polishing/Rectifying Sawn Tile Edges Neaten the edge in seconds, simply passing the Diamond Edge Polisher along the edge provides that professional finish in seconds and prevents...- from £24.60

- from £24.60

- Unit price

- per

-

Marcrist DF550 Diamond Angle Grinder Flap Disc

The DF550 Diamond Flap Wheel – M14 is a top-quality flap disc. This product serves professionals who need effective and accurate coarse grinding. This manufacturer creates this flap disc for the grinder using high-quality diamond abrasives. It quickly removes material while keeping a smooth...- £49.68

- £49.68

- Unit price

- per

-

Marcrist FF750 Diamond Finger Milling Bit 20x65mm M14

Precision high-speed diamond Finger Milling Bits Ø 20 mm x M14 for angle grinders. The FF750 Diamond Router is a precision high-speed diamond finger milling bit designed for Ø 20 mm x M14 angle grinders. This versatile tool is ideal for a variety of...- £39.13

- £39.13

- Unit price

- per

-

Nylon Flexible Backing Pad with Flange

Ø 115mm & 125mm backing pad for fibre discs Flexible Pad complete with M14 flange nut for Ø 115mm (4 ½" & 125mm (5" ) grinders For the safe & vibration reduced use of fibre discs and semi-flexible abrasives. Features & Benefits Flexible...- from £4.32

- from £4.32

- Unit price

- per